Overview

AES Food Equipment collaborated with The Newt in Somerset to create a cutting edge butchery facility at Avalon Farm. Designed to enhance meat production and supply capabilities, this standalone facility supports The Newt’s hotel, retail outlets, and online shop, with a focus on quality, provenance, and sustainability.

The Challenge

The Newt required a facility that could handle full-carcass butchery across various species while maintaining rigorous hygiene, efficiency, and traceability standards. AES Food Equipment was entrusted with delivering a custom stainless steel meat rail system, along with essential hygiene and butchery equipment, all tailored to meet The Newt’s unique requirements.

Our Approach

Collaborative Design & Planning

Working alongside The Newt and their architects, AES Food Equipment contributed critical insights into the design of the loading bays, meat chillers, and butchery preparation rooms. These details enabled the architects to prepare comprehensive tender documents for contractors. During the tendering process, we supported contractors by addressing technical questions to ensure smooth bidding.

Partnering with CG Fry & Son

After CG Fry & Son won the tender, AES collaborated closely with them and The Newt throughout construction. This partnership ensured the seamless integration of our twin track stainless steel meat rail system and other equipment into the facility’s design.

Tailored Solutions

AES supplied and installed key equipment to meet The Newt’s needs:

- Twin-track stainless steel rail system for efficient carcass handling.

- Hygiene equipment, including boot and apron washes, to ensure compliance with food safety standards.

- A carcass loading arm to simplify loading onto the rail system.

The meat chiller was equipped with a stunning glass viewing panel, allowing visitors to observe the butchery process in action.

The Result

The completed facility at Avalon Farm combines aesthetic design with practical functionality. Clad in glass and oak, the butchery reflects The Newt’s commitment to transparency and quality. It features a production area for full-carcass processing and a workshop space for training and education.

This facility now supplies beef, lamb, and venison from Avalon Farm, alongside locally sourced pork and poultry, to The Newt’s estate, shops, and online business. Visitors can experience the craft of butchery firsthand through workshops and training initiatives.

Client Testimonial

"Our new butchery has transformed the way we handle and showcase meat at The Newt. The collaborative efforts with AES Food Equipment have resulted in a facility that’s as functional as it is beautiful. It’s a space where craft and care come together, and it’s integral to our farm-to-table approach."– The Newt

Learn More

For more information about The Newt’s butchery and their commitment to high-welfare meat production, visit their official website.

Overview

Gloucester Services, renowned for its award winning farm shop and restaurant, approached AES Food Equipment to address a significant operational and safety challenge within their onsite butchery. Known for their farm to fork philosophy, Gloucester Services needed a solution that not only improved the efficiency of their butchery but also enhanced the visual appeal of their produce for customers.

The Challenge

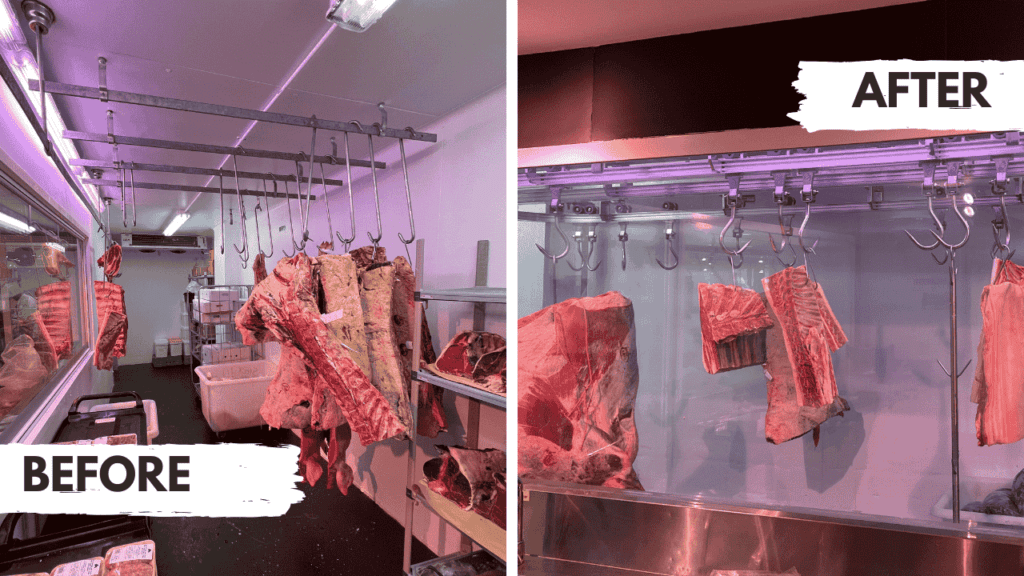

The existing meat handling process at Gloucester Services required staff to manually carry carcasses from the loading bay through a corridor into the butchery, causing inefficiencies and potential health and safety risks. Meat was displayed using a flat bar rail system suspended from ceiling panels, one of which had failed, posing a serious hazard.

Due to the layout constraints of the shop, installing a traditional meat rail system from the loading bay was not feasible. AES was tasked with designing a solution that would:

- Eliminate the risk of ceiling panel failures.

- Improve the efficiency of stock rotation and meat handling.

- Create a visually engaging display of meats through the glass viewing window into the shop.

Our Approach

Bespoke Design for Space Constraints

After assessing the site, AES designed and installed a self-supporting meat rail system that operated independently of the ceiling panels. This steel-structured solution ensured:

- Enhanced safety – no weight was transferred to the ceiling, mitigating the risk of collapse.

- Efficient stock rotation – the new system allowed for smooth movement of carcasses, reducing manual handling.

- Visual appeal – cuts of meat could now be showcased effectively through the glass viewing panel, enhancing the customer experience.

On-Site Installation and Testing

AES worked around the operational hours of Gloucester Services to install the new rail system with minimal disruption. The self-supporting structure was designed to seamlessly integrate into the butchery, allowing staff to lift cuts of meat directly from the rail for preparation.

Maximising Customer Engagement

The revamped display turned the butchery into a visual centrepiece within the farm shop, aligning with Gloucester Services’ ethos of transparency and local produce promotion. Customers could now witness the quality and craftsmanship behind the counter, reinforcing trust and driving sales.

The Result

The installation of the self-supporting meat rail system has significantly enhanced both the safety and operational efficiency of Gloucester Services’ butchery. Not only has the risk of ceiling panel failure been eliminated, but the improved layout also provides a more immersive experience for customers. The butchery now serves as a showcase of locally sourced meats, reinforcing the farm-to-fork philosophy that Gloucester Services is celebrated for.

"The new self-supporting meat rail system has been a game-changer for us. It not only resolved the health and safety issues we faced but also enhanced how we display our meats to customers. The visibility through the viewing window has created a real talking point, allowing us to showcase the quality of our produce directly to those passing through our services."

Gloucester Services Butchery Manager

About Gloucester Services

Located on the M5 Southbound, Gloucester Services is one of the UK’s leading service stations, famous for its locally sourced produce, farm shop, and restaurant. A destination in itself, Gloucester Services offers travelers a unique experience that celebrates British farming and artisan food production.

Learn more about Gloucester Services here.

Over the last 50 years, various meat rail systems have been employed to hang and transport carcass meat within meat production facilities. In this blog, we will explore these types of meat rail systems, examining the benefits and drawbacks of each, and providing recommendations on the most suitable systems for your meat processing business.

Round Bar/Tubular Systems

Round bar or tubular meat rail systems remain widely used in the UK across abattoirs, cutting plants, and butcheries. This system consists of a steel framework with galvanised metal hangers at varying heights, supporting steel tubes for meat skids and tubular roller hooks. Directional changes are managed via switches, available in 25, 45, and 90-degree turns, with newer rollover designs enhancing operator safety by preventing hooks from falling off the ends.

Commonly, the rail tubes are either 48mm or 60mm in diameter, with 60mm being prevalent in Europe. Notable manufacturers of round bar meat rail systems include Couedic Madore and Hocker. These systems can also feature pneumatic switches, allowing operators to change directions using a controller, where a ram turns over the switch.

Advantages:

- Cost-effective, using tubular galvanised tubes.

- Meat skids can double as hooks.

Disadvantages:

- Requires regular greasing for smooth hook movement.

- Potential safety issues with hooks detaching.

- Complex structural support may cause installation challenges.

Aluminium/Stainless Steel Twin Track Meat Rail Systems

Aluminium and stainless steel twin track systems are the leading meat rail systems in the UK market, due to their numerous advantages. These systems feature a steel supporting framework with hangers that clip onto I-beams, holding two single extruded track profiles. The system utilises plastic-wheeled rollers for easy carcass movement.

Various switches, including 45 and 90-degree turns, as well as 3-way or 4-way directional switches, facilitate complex operational workflows. Notable manufacturers of twin track meat rail systems include Transuni, Biralux, Abachem and AES.

Advantages:

- High safety, preventing hook dislodgment.

- Easy carcass movement due to plastic rollers with bearings.

- No need for greasing, reducing maintenance and cleaning efforts.

- Corrosion-resistant materials like aluminium and stainless steel.

- Easy to upgrade or modify without specialist machinery.

Disadvantages:

- Space requirements for installation, particularly in smaller chillers or cold rooms.

- Necessitates a supporting structure.

Flat Bar Systems

Once common in the UK, flat bar systems are now primarily used in North American meat processing facilities. These systems, supported by a steel framework, involve a flat bar where hooks with single wheels sit on top.

Advantages:

- Cost-effective.

Disadvantages:

- Lack of available flat bar switches.

- Safety concerns with hook attachment.

- Susceptibility to rust.

Self-Supporting Aluminium Rails

This modern European meat rail system integrates a self-supporting aluminium structure, simplifying design and installation. The system features plastic switches and pulls for directional changes, with hooks seated on small wheels inside the rail. Notable manufacturers of self supporting rail systems include Italmodular and Tonon.

Advantages:

- Streamlined design and installation process.

Disadvantages:

- Lower SWL (Safe Working Load) for hooks.

- Requires numerous supporting columns, impacting floor space.

- Potential operational delays due to sticking plastic components.

Choosing the Right Meat Rail System

Selecting the appropriate types of meat rail system depends on several factors: existing infrastructure, available supporting steelwork, facility size, and operational requirements. Generally, the aluminium twin track rail system is recommended for most meat processing facilities. At AES Food Equipment, we distribute leading suppliers of this rail type and can match your existing layouts.

For more information or to discuss your specific requirements, please contact us.