Hygiene isn’t just a box to tick for compliance—it’s the foundation of trust between food businesses and their customers. Whether you’re running a small deli or a large-scale processing plant, investing in high-quality hygiene equipment and following best practices can safeguard your reputation and products.

Step 1: Identify Critical Control Points

Every workspace has high-risk areas, and identifying these is the first step to building an effective hygiene routine. From preparation surfaces to foot traffic zones, focus on areas where cross-contamination is most likely to occur.

Step 2: Invest in Industry-Specific Hygiene Equipment

Not all tools are created equal, and using the right hygiene equipment can save you time and effort. Consider these essentials:

- Utensil Washers: Perfect for thoroughly cleaning knives, cutting boards, and other small tools.

- Euro Bin Washers: Ideal for maintaining cleanliness of large storage containers.

- Boot Wash Stations: A must-have for facilities where staff move between different zones, reducing contamination risks.

- Pallet Washers: Ensures pallets used in transport and storage remain free from contaminants.

Step 3: Establish a Cleaning Schedule

Consistency is key. Create a daily, weekly, and monthly cleaning schedule tailored to your facility’s needs. Ensure that tasks like sanitising utensils, cleaning work surfaces, and maintaining equipment are clearly outlined.

Step 4: Train Your Team on Proper Hygiene Practices

Even the best hygiene equipment can’t do the job without trained staff. Provide clear instructions on how to use the tools correctly and emphasise the importance of maintaining a clean workspace. Regular refresher courses can help reinforce these habits.

Step 5: Monitor and Maintain Your Equipment

Properly maintaining your hygiene equipment ensures it stays effective for longer. Regularly inspect machinery for wear and tear, and replace any damaged parts promptly. Clean equipment after every use to prevent buildup of grease or food residue, which can compromise performance.

Why Hygiene Equipment Matters for Your Business

Investing in reliable hygiene equipment doesn’t just simplify your cleaning processes—it protects your customers, staff, and reputation. By integrating the right tools into your daily operations, you’ll be able to confidently meet industry standards and ensure customer satisfaction every step of the way.

Explore our hygiene equipment at AES Food Equipment today.

In the food industry, cleanliness is essential for safety. Whether you’re handling meat, diary, or packaged goods, maintaining hygiene standards is critical for protecting both your business and your customers. Investing in high-quality hygiene equipment is one of the most effective ways to ensure that your operation meets the requirements and guarantees contaminant-free food.

The Role of Hygiene Equipment in the Food Industry

Hygiene, from the farm to the kitchen, is a key factor in every stage of food production. This is especially true in environments where contamination risks are high, such as butchery, abattoirs, and food processing plants. Hygiene equipment, when used properly, ensures that surfaces, utensils, and machines are thoroughly cleaned and sanitised.

Industrial washing systems, utensil washers, and other hygiene equipment are designed to efficiently remove bacteria, dirt, and other harmful substances from tools and surfaces. With the right systems in place, businesses can reduce the risk of contamination, avoid costly downtime due to cleaning issues, and increase productivity by streamlining hygiene processes.

Compliance with Food Safety Standards

The food industry is governed by strict hygiene and safety standards, including regulations set by the Food Safety Act, HACCP (Hazard Analysis Critical Control Point), and local health authorities. These standards help ensure that the food produced is safe for consumption and free from harmful contaminants.

To comply with these standards, businesses need to invest in high-quality hygiene equipment that can handle the rigorous demands of cleaning and sanitising large quantities of tools, equipment, and work areas. Industrial washing systems are particularly beneficial in this regard, as they provide a thorough clean while reducing human error and contamination risk.

The Cost of Poor Hygiene

While investing in hygiene equipment may seem like a large upfront cost, the long-term savings and benefits are undeniable. Poor hygiene practices can lead to a variety of costly issues:

- Contamination: Bacteria, pathogens, and other contaminants can quickly spread throughout a facility, leading to product recalls, lost revenue, and damage to your business’s reputation.

- Downtime: If equipment or tools are not properly sanitised, it can lead to production delays or halts, costing your business valuable time and resources.

- Health and Safety Risks: Failing to maintain hygiene standards puts both your workers and customers at risk. This could result in legal action or fines if your business is found to be non-compliant with safety regulations.

Investing in quality hygiene equipment mitigates these risks and protects your business from the costs of non-compliance or contamination.

The Long-Term Benefits of High-Quality Hygiene Equipment

When it comes to hygiene systems, you get what you pay for. By investing in robust, reliable equipment, businesses can see significant improvements in several areas:

- Efficiency: High-quality equipment provides faster and more thorough cleaning, helping to reduce downtime and increase productivity.

- Reduced Manual Labour: Automated systems, such as utensil washers or pallet washers, minimise the need for manual cleaning, saving time and reducing the risk of human error.

- Consistency: Quality hygiene equipment ensures a consistent level of cleanliness, making it easier to meet industry standards and customer expectations.

- Sustainability: Many modern hygiene systems are designed to be more water- and energy-efficient, helping businesses reduce their environmental impact while also lowering utility costs.

Conclusion

In the competitive food industry, maintaining hygiene standards is non-negotiable. Not only does it help ensure compliance with food safety regulations, but it also protects your business from the risks and costs associated with poor hygiene practices. By investing in quality hygiene equipment, you can streamline your operations, reduce risks, and improve overall productivity.At AES Food Equipment, we understand the importance of cleanliness and offer a range of industrial washing systems and hygiene equipment to help your business meet the highest hygiene standards. Whether you’re looking for utensil washers, pallet washers, or customised hygiene solutions, we have the tools you need to keep your operations running smoothly and safely.

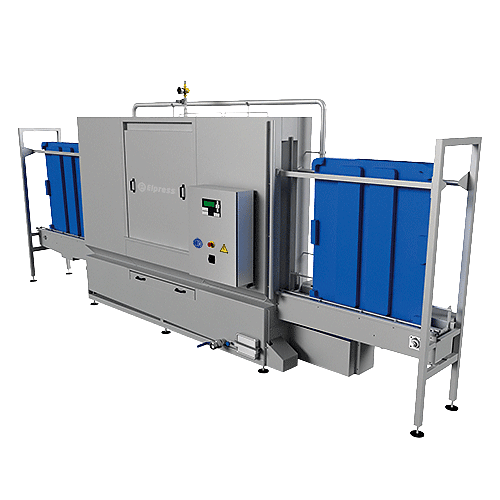

Pallets are essential for efficient storage and transportation of goods in warehouses and industrial facilities, such as food production plants. However, over time pallets accumulate dirt, spills and other contaminants which can lead to product contamination and pose health and safety risks if left uncleaned.

Investing in an automated pallet washing system is an effective solution to thoroughly clean pallets while saving time and labour costs. This article provides key factors to consider when selecting the right pallet washer for your business.

Assess Your Pallet Washing Needs

The first step is to analyse your current pallet washing process and requirements. Consider the volume of pallets that need cleaning, the level of contamination, and the regularity of washing needed.

Manual pallet washing involves workers cleaning pallets by hand using brushes, water and detergent. It is labour-intensive and inconsistent. Automated pallet washers use specialised spray systems to efficiently clean pallets. They deliver a thorough, uniform wash and are less labour-intensive than manual washing.

Consider the Wash Process

Look for washers with distinct wash zones for cleaning, rinsing and drying. The cleaning zone should use robust wash arms or rotating jets to provide strong mechanical cleaning. Rinsing zones will rinse off detergents with fresh water. Infrared or spin drying systems help maximise drying. Choose washers with adjustable washing pressures and temperatures for versatile washing programmes.

Evaluate Capacity and Footprint

Consider the washer's capacity – the number of pallets washed per hour. Select the appropriate capacity aligned with your volumes. Also, examine the physical footprint. Confirm that it will fit within your facility layout and allow ease of access for loading and unloading pallets. A compact washer with a small footprint can be advantageous for space-constrained facilities.

Review Safety Features

Choose a washer with adequate safety mechanisms. Look for emergency stop buttons, pressure gauges, automatic shut-offs and low-water protection. These features help prevent accidents and mechanical damage. Door interlocks that pause operation when opened are also useful. Check for inbuilt chemical dosing to avoid manual chemical handling.

Ensure Compliance with Regulations

Select a washer compliant with UK regulations. It should meet EHEDG hygiene guidelines and have CE marking certified by EU safety standards. Compliance indicates the washer is safe, hygienic and reliable for commercial facilities.

Consider Energy Efficiency

An energy efficient washer will help minimise operating costs and environmental impact. Seek washers with heat recovery, low power consumption, and precise dosing of water and detergents. Variable speed pumps and electric drives provide energy savings compared to standard motors.

Check Additional Features

Added features can optimise washing performance and usability. Look for programmable control panels allowing custom wash settings. Mobility including castors enables convenient movement. Washer sanitation cycles prevent cross-contamination. Modular construction allows customisation.

Review After-Sales Support Services

Check the manufacturer provides installation, maintenance, spare parts supply and repair services. Onsite maintenance training also adds value. These after-sales services ensure the smooth running of your washer and give you technical support.

By carefully analysing your requirements, scrutinising washer specifications, and selecting the right commercial provider, you can invest in a pallet washing system tailored to your operational needs. The right pallet washer will deliver consistent, high-quality washing vital for your productivity and profits.

In the food processing industry, maintaining excellent hygiene standards is absolutely critical. Any lapses can lead to contamination, illness, and damage to your reputation. Investing in proper industrial washing systems for your food processing equipment is one of the most important things you can do to uphold rigorous hygiene protocols. In this blog, we’ll explore how industrial washers keep your food processing machines clean and sanitary. Whether you’re operating a bakery, dairy, meat processing plant or any other food facility, read on for key guidance on preserving pristine conditions with tailored washing systems.

The Importance of Hygienic Food Processing Equipment

Food processing equipment must be kept clean at all times. Any residues left on surfaces can transfer to food products. For example, Listeria is a harmful bacterium that thrives in food plants. It can lurk on equipment if cleaning is inadequate. Industrial washing systems are designed to thoroughly clean machines and prevent these hazards. Keeping equipment hygienically clean should be a top priority for safety and reputation.

How Industrial Washing Systems Maintain Hygiene

Industrial washing systems are specifically designed to eliminate bacteria, residues, and other contaminants from food processing equipment through intensive cleaning. Here's how they maintain superb hygiene:

- Powerful Wash Action - Industrial washers use concentrated jets, high water volumes, and specialised detergents to generate powerful washing action that breaks down and dissolves soils.

- Elevated Temperatures - Washing at hot temperatures (around 82°C) kills bacteria and loosens baked-on food deposits.

- Rinsing - Thorough rinsing flushes away cleaning chemicals that could otherwise taint food products if left on surfaces.

- Sanitisation - Heat, chemical sanitisers, or both are used after washing for extra antimicrobial protection.

- Drying - Surfaces are dried post-wash to prevent moisture accumulation where bacteria can thrive.

- Validation - Industrial washers undergo validation testing to verify their ability to reduce microbes to safe levels on equipment.

- Automation - Features like timed cycles, temperature monitoring, and chemical dosing eliminate human error and ensure consistent, effective washing.

When used properly, industrial washing systems reliably clean food processing machinery to the high standards demanded in the industry.

How to Maintain Wash Efficacy

Industrial washing systems deliver intensive cleaning, but their performance can slip over time. To maintain wash efficacy:

- Monitor wash temperatures and chemical levels. Top up chemicals and recalibrate as required.

- Inspect equipment closely after washing - if any soils remain, reassess your wash program.

- Swab test random equipment for microbial contamination.

- Keep the interior of the washing system clean to avoid soil buildup.

- Watch for biofilm formation inside hoses and nozzles and perform deep cleans.

- Check spray jets regularly and clear any blocked holes immediately.

With close monitoring and preventative maintenance, your industrial washer will uphold brilliant hygiene standards for the long run.

Choosing an Effective Industrial Washing System

When searching for industrial washing systems, it’s important to choose one that is suited to your facility’s needs. Conveyor washers, crate washers, and hot water sterilisers are common options. Consider your workload, equipment types, and output when selecting a system.

Proper hygiene is vital in food manufacturing. Tailored industrial washing systems give you the intensive cleaning capability needed to keep food processing equipment pristine. Implementing best practices around cycles, temperatures, and chemicals, along with vigilant maintenance, will maintain superb hygiene for years on end.