Maintaining proper hygiene in food processing environments is not just important—it’s critical. The right hygiene equipment ensures that food safety standards are met, reducing the risk of contamination and ensuring the quality of your product. Here’s why investing in top-tier hygiene equipment is essential for food processors.

1. The Importance of Hand Hygiene

Hand hygiene is one of the most critical aspects of food safety. Automated hand wash stations, equipped with soap dispensers and dryers, ensure that employees maintain proper hygiene standards before entering food processing areas. This helps reduce the spread of harmful bacteria and contaminants.

- Compliance with Regulations: Ensuring that hand hygiene practices are followed can help facilities stay compliant with health and safety regulations.

- Employee Training: Regular training sessions can reinforce the importance of hand hygiene and proper usage of hand washing equipment.

2. Boot Washing Systems

In high-traffic food production facilities, boot washing stations are essential for maintaining sanitary conditions. These systems clean and disinfect footwear before employees enter food processing areas, preventing the spread of dirt, bacteria, and other contaminants.

- Types of Boot Washers:

- Manual Boot Washers: Cost-effective and easy to maintain.

- Automated Systems: Provide thorough cleaning and are ideal for larger operations where speed and efficiency are critical.

- Installation Considerations: Placement should be convenient for all employees to encourage regular use.

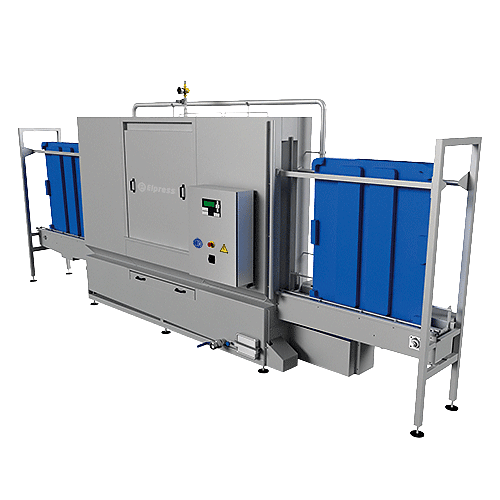

3. Industrial Washing Systems

For larger-scale operations, industrial washing systems are indispensable. They efficiently clean and sanitise crates, trays, and other equipment that come into contact with food, ensuring that every part of your production line remains hygienic and compliant with industry standards.

- Energy and Water Efficiency: Look for systems that minimise water usage while maintaining high standards of cleanliness.

- Maintenance Tips: Regular servicing of washing systems will prevent breakdowns and ensure optimal performance.

4. Investing in Hygiene Equipment

Investing in high-quality hygiene equipment might seem like a significant upfront cost, but it pays off in the long run by reducing the risk of foodborne illness, ensuring compliance with regulations, and protecting your brand’s reputation. With equipment like hand sanitising stations, boot washers, and industrial washers, you can create a safer, more efficient food processing environment.

- Choosing the Right Equipment: Assess the specific needs of your facility, including the types of products processed and the volume of output.

- Budgeting: Consider long-term savings through reduced waste and compliance costs when making investments.

5. Best Practices for Hygiene Management

To ensure a hygienic environment, establish and enforce best practices in your facility. Regularly audit hygiene equipment, maintain cleanliness protocols, and stay updated with industry guidelines.

- Continuous Training: Provide ongoing training to employees about hygiene best practices and the proper use of hygiene equipment.

- Regular Audits: Conduct routine inspections to ensure all hygiene equipment is functioning properly and being used correctly.

Check out our selection of hygiene equipment at AES Food Equipment today, your number one partner for quality food equipment and supplies.

Pallets are essential for efficient storage and transportation of goods in warehouses and industrial facilities, such as food production plants. However, over time pallets accumulate dirt, spills and other contaminants which can lead to product contamination and pose health and safety risks if left uncleaned.

Investing in an automated pallet washing system is an effective solution to thoroughly clean pallets while saving time and labour costs. This article provides key factors to consider when selecting the right pallet washer for your business.

Assess Your Pallet Washing Needs

The first step is to analyse your current pallet washing process and requirements. Consider the volume of pallets that need cleaning, the level of contamination, and the regularity of washing needed.

Manual pallet washing involves workers cleaning pallets by hand using brushes, water and detergent. It is labour-intensive and inconsistent. Automated pallet washers use specialised spray systems to efficiently clean pallets. They deliver a thorough, uniform wash and are less labour-intensive than manual washing.

Consider the Wash Process

Look for washers with distinct wash zones for cleaning, rinsing and drying. The cleaning zone should use robust wash arms or rotating jets to provide strong mechanical cleaning. Rinsing zones will rinse off detergents with fresh water. Infrared or spin drying systems help maximise drying. Choose washers with adjustable washing pressures and temperatures for versatile washing programmes.

Evaluate Capacity and Footprint

Consider the washer's capacity – the number of pallets washed per hour. Select the appropriate capacity aligned with your volumes. Also, examine the physical footprint. Confirm that it will fit within your facility layout and allow ease of access for loading and unloading pallets. A compact washer with a small footprint can be advantageous for space-constrained facilities.

Review Safety Features

Choose a washer with adequate safety mechanisms. Look for emergency stop buttons, pressure gauges, automatic shut-offs and low-water protection. These features help prevent accidents and mechanical damage. Door interlocks that pause operation when opened are also useful. Check for inbuilt chemical dosing to avoid manual chemical handling.

Ensure Compliance with Regulations

Select a washer compliant with UK regulations. It should meet EHEDG hygiene guidelines and have CE marking certified by EU safety standards. Compliance indicates the washer is safe, hygienic and reliable for commercial facilities.

Consider Energy Efficiency

An energy efficient washer will help minimise operating costs and environmental impact. Seek washers with heat recovery, low power consumption, and precise dosing of water and detergents. Variable speed pumps and electric drives provide energy savings compared to standard motors.

Check Additional Features

Added features can optimise washing performance and usability. Look for programmable control panels allowing custom wash settings. Mobility including castors enables convenient movement. Washer sanitation cycles prevent cross-contamination. Modular construction allows customisation.

Review After-Sales Support Services

Check the manufacturer provides installation, maintenance, spare parts supply and repair services. Onsite maintenance training also adds value. These after-sales services ensure the smooth running of your washer and give you technical support.

By carefully analysing your requirements, scrutinising washer specifications, and selecting the right commercial provider, you can invest in a pallet washing system tailored to your operational needs. The right pallet washer will deliver consistent, high-quality washing vital for your productivity and profits.

The meat processing industry in the UK handles millions of animals and tons of meat products each year. Having equipment that efficiently performs processing tasks while maintaining high safety and quality standards is critical for meat processors. In this post, we'll look at the importance of choosing high-quality industrial meat processing equipment from experienced suppliers like us.

Improved Efficiency and Productivity

One of the biggest advantages of investing in quality commercial meat processing equipment is improved efficiency and productivity. Well-designed meat processing equipment is engineered to handle large volumes quickly while minimising waste.

For example, high-performance industrial meat grinders can grind hundreds of pounds of meat per hour. Advanced mixing equipment can thoroughly blend large batches of meat and other ingredients in minutes. Fast production improves throughput and allows processors to maximise yields. Less waste means higher profits.

Better Safety and Hygiene

Meat processing involves working with raw and cooked meats, bones, fats, and other animal byproducts. In this industry, food safety is paramount. Quality commercial meat processing equipment is made from materials that make it easy to thoroughly clean and sanitise. Equipment designed with hygiene in mind reduces contamination risks.

Reputable manufacturers and suppliers also offer machines with advanced safety features. This includes things like emergency stop buttons, guards, and sensors. Protecting worker health should be a top priority, and the best equipment is engineered with safety in mind. Investing in equipment built for excellent hygiene and safety helps meat processors prevent issues and avoid costly product recalls.

Improved Quality and Consistency

Consistency and quality are essential for creating profitable meat products that consumers want to buy again and again. Advanced meat processing equipment enables processors to achieve exceptional quality and uniformity batch after batch.

Efficient mixers blend meats and other ingredients to perfection for consistent textures and flavours. Specialised massagers integrate seasonings into meats evenly. High-performance grinders uniformly process meat to any desired fineness. Properly calibrated smokers infuse meats with just the right amount of smoke flavour. Quality packaging equipment produces professional, appealing packages. Premium equipment leads to premium meat products.

Better Inventory Management

Processed meat products have defined shelf lives. Efficient equipment allows processors to improve inventory management. When production is smooth and efficient, it's easier to manufacture the right quantities to closely match supply with demand. Less waste means lower costs. And producing inventory as needed reduces storage requirements. The productivity features of quality equipment enable processors to improve their inventory management practices.

Partner with a Trusted Equipment Expert

When selecting commercial meat processing equipment suppliers, it’s important to partner with reputable firms. Established providers, such as ourselves, understand the needs of local meat processors. We carry industrial meat processing equipment to handle the unique requirements of the regional meat industry. Our knowledgeable teams can help processors select the right equipment, provide installation support, and assist with maintenance and parts needs.

The right commercial meat processing equipment allows meat processors to achieve higher throughputs, lower costs, better inventory management, exceptional quality and consistency, higher profits, and globally recognised food safety standards. Investing in quality equipment from reputable suppliers will serve any meat processing operation well for years to come.