Maintaining Hygiene with Industrial Washing Systems

In the food processing industry, maintaining excellent hygiene standards is absolutely critical. Any lapses can lead to contamination, illness, and damage to your reputation. Investing in proper industrial washing systems for your food processing equipment is one of the most important things you can do to uphold rigorous hygiene protocols. In this blog, we’ll explore how industrial washers keep your food processing machines clean and sanitary. Whether you’re operating a bakery, dairy, meat processing plant or any other food facility, read on for key guidance on preserving pristine conditions with tailored washing systems.

The Importance of Hygienic Food Processing Equipment

Food processing equipment must be kept clean at all times. Any residues left on surfaces can transfer to food products. For example, Listeria is a harmful bacterium that thrives in food plants. It can lurk on equipment if cleaning is inadequate. Industrial washing systems are designed to thoroughly clean machines and prevent these hazards. Keeping equipment hygienically clean should be a top priority for safety and reputation.

How Industrial Washing Systems Maintain Hygiene

Industrial washing systems are specifically designed to eliminate bacteria, residues, and other contaminants from food processing equipment through intensive cleaning. Here's how they maintain superb hygiene:

- Powerful Wash Action - Industrial washers use concentrated jets, high water volumes, and specialised detergents to generate powerful washing action that breaks down and dissolves soils.

- Elevated Temperatures - Washing at hot temperatures (around 82°C) kills bacteria and loosens baked-on food deposits.

- Rinsing - Thorough rinsing flushes away cleaning chemicals that could otherwise taint food products if left on surfaces.

- Sanitisation - Heat, chemical sanitisers, or both are used after washing for extra antimicrobial protection.

- Drying - Surfaces are dried post-wash to prevent moisture accumulation where bacteria can thrive.

- Validation - Industrial washers undergo validation testing to verify their ability to reduce microbes to safe levels on equipment.

- Automation - Features like timed cycles, temperature monitoring, and chemical dosing eliminate human error and ensure consistent, effective washing.

When used properly, industrial washing systems reliably clean food processing machinery to the high standards demanded in the industry.

How to Maintain Wash Efficacy

Industrial washing systems deliver intensive cleaning, but their performance can slip over time. To maintain wash efficacy:

- Monitor wash temperatures and chemical levels. Top up chemicals and recalibrate as required.

- Inspect equipment closely after washing - if any soils remain, reassess your wash program.

- Swab test random equipment for microbial contamination.

- Keep the interior of the washing system clean to avoid soil buildup.

- Watch for biofilm formation inside hoses and nozzles and perform deep cleans.

- Check spray jets regularly and clear any blocked holes immediately.

With close monitoring and preventative maintenance, your industrial washer will uphold brilliant hygiene standards for the long run.

Choosing an Effective Industrial Washing System

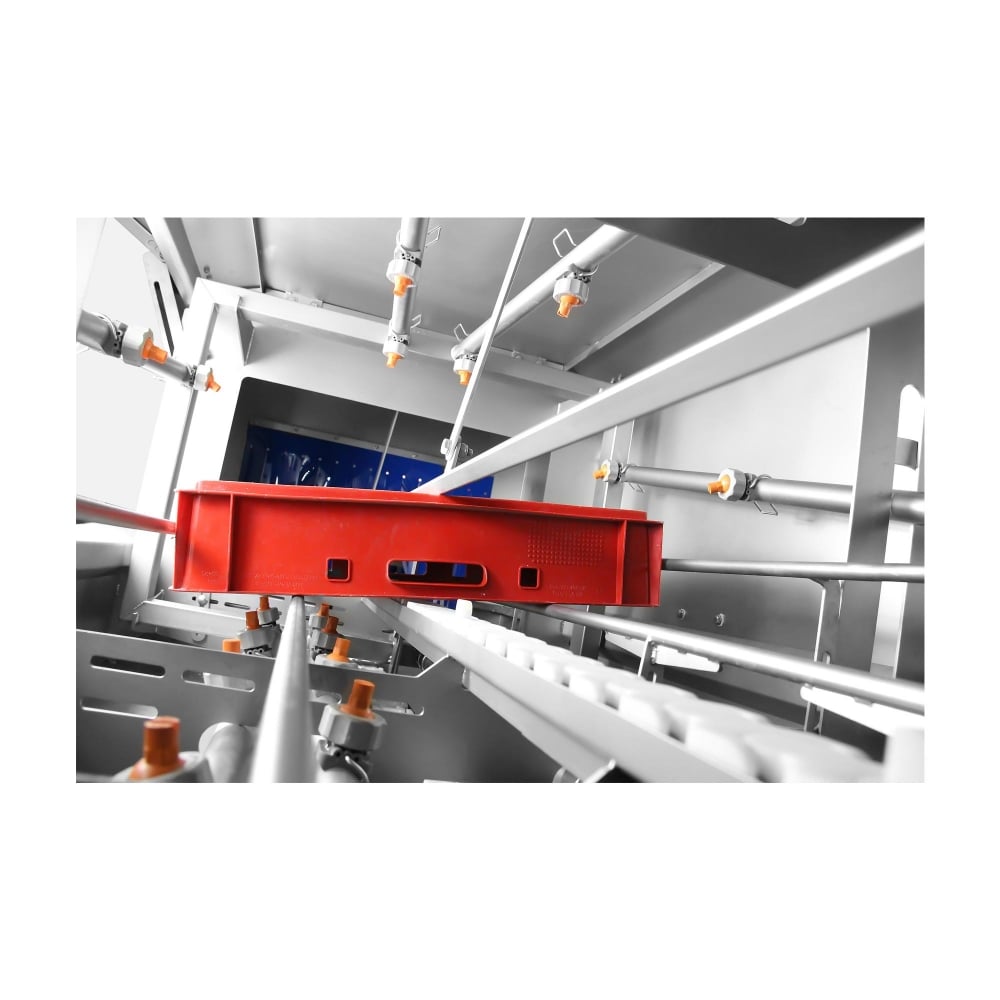

When searching for industrial washing systems, it’s important to choose one that is suited to your facility’s needs. Conveyor washers, crate washers, and hot water sterilisers are common options. Consider your workload, equipment types, and output when selecting a system.

Proper hygiene is vital in food manufacturing. Tailored industrial washing systems give you the intensive cleaning capability needed to keep food processing equipment pristine. Implementing best practices around cycles, temperatures, and chemicals, along with vigilant maintenance, will maintain superb hygiene for years on end.