How to Choose the Right Pallet Washer

Pallets are essential for efficient storage and transportation of goods in warehouses and industrial facilities, such as food production plants. However, over time pallets accumulate dirt, spills and other contaminants which can lead to product contamination and pose health and safety risks if left uncleaned.

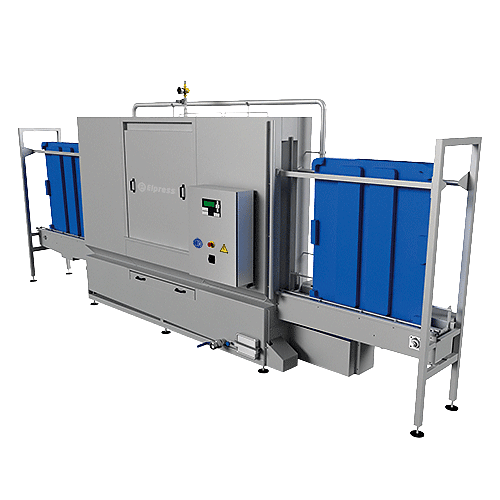

Investing in an automated pallet washing system is an effective solution to thoroughly clean pallets while saving time and labour costs. This article provides key factors to consider when selecting the right pallet washer for your business.

Assess Your Pallet Washing Needs

The first step is to analyse your current pallet washing process and requirements. Consider the volume of pallets that need cleaning, the level of contamination, and the regularity of washing needed.

Manual pallet washing involves workers cleaning pallets by hand using brushes, water and detergent. It is labour-intensive and inconsistent. Automated pallet washers use specialised spray systems to efficiently clean pallets. They deliver a thorough, uniform wash and are less labour-intensive than manual washing.

Consider the Wash Process

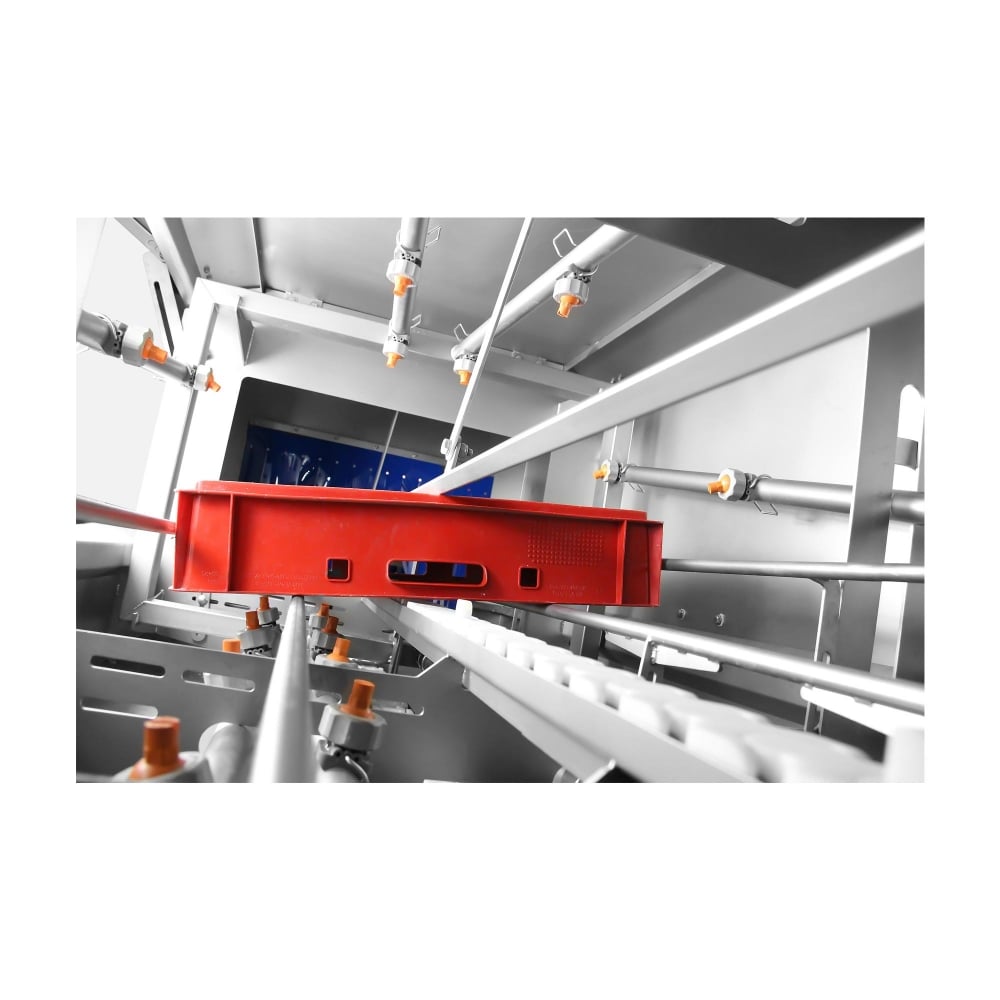

Look for washers with distinct wash zones for cleaning, rinsing and drying. The cleaning zone should use robust wash arms or rotating jets to provide strong mechanical cleaning. Rinsing zones will rinse off detergents with fresh water. Infrared or spin drying systems help maximise drying. Choose washers with adjustable washing pressures and temperatures for versatile washing programmes.

Evaluate Capacity and Footprint

Consider the washer's capacity – the number of pallets washed per hour. Select the appropriate capacity aligned with your volumes. Also, examine the physical footprint. Confirm that it will fit within your facility layout and allow ease of access for loading and unloading pallets. A compact washer with a small footprint can be advantageous for space-constrained facilities.

Review Safety Features

Choose a washer with adequate safety mechanisms. Look for emergency stop buttons, pressure gauges, automatic shut-offs and low-water protection. These features help prevent accidents and mechanical damage. Door interlocks that pause operation when opened are also useful. Check for inbuilt chemical dosing to avoid manual chemical handling.

Ensure Compliance with Regulations

Select a washer compliant with UK regulations. It should meet EHEDG hygiene guidelines and have CE marking certified by EU safety standards. Compliance indicates the washer is safe, hygienic and reliable for commercial facilities.

Consider Energy Efficiency

An energy efficient washer will help minimise operating costs and environmental impact. Seek washers with heat recovery, low power consumption, and precise dosing of water and detergents. Variable speed pumps and electric drives provide energy savings compared to standard motors.

Check Additional Features

Added features can optimise washing performance and usability. Look for programmable control panels allowing custom wash settings. Mobility including castors enables convenient movement. Washer sanitation cycles prevent cross-contamination. Modular construction allows customisation.

Review After-Sales Support Services

Check the manufacturer provides installation, maintenance, spare parts supply and repair services. Onsite maintenance training also adds value. These after-sales services ensure the smooth running of your washer and give you technical support.

By carefully analysing your requirements, scrutinising washer specifications, and selecting the right commercial provider, you can invest in a pallet washing system tailored to your operational needs. The right pallet washer will deliver consistent, high-quality washing vital for your productivity and profits.