Cattle Hide Puller – DHB

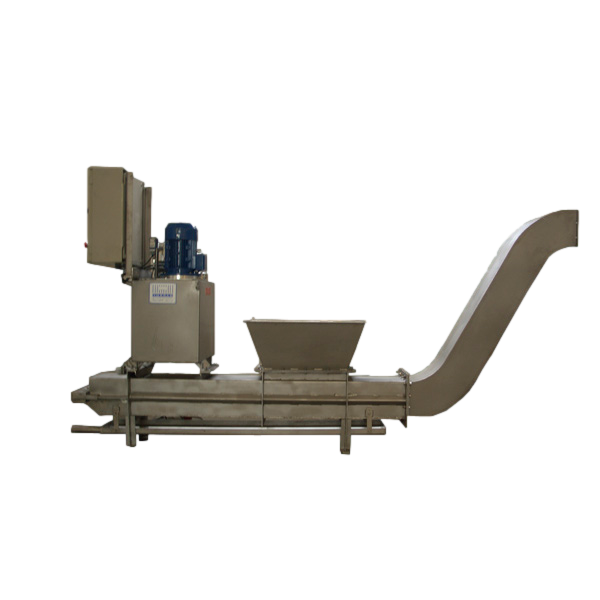

The cattle hide puller / dehider facilitates the removal of the hide from top to bottom. Additionally, when the network height permits, it enables head dehiding. Its hydraulic system provides both strength and flexibility, ensuring the hide is removed without tearing.

- Made in stainless steel

- Comply with the Machinery Directive

- Hydraulic power

- Intensified safety

- Recognised reliability

- Reduced maintenance

- Fast Delivery

- Expert Advice

- Exclusive Deals

Features & Benefits

This machine adheres to hygiene standards, ensuring that dehiding is performed from the top downwards, preventing the hide from contaminating the carcass. It requires two operators for optimal functionality. These operators are positioned in side baskets made of stainless steel, which move in sync with the hide-pulling process. They control the upward and downward motions while the hide wraps around a stainless steel drum.

Operators guide the hide using either a perco or a knife. The hide is suspended by two chains that feature automatic unhooking during unwinding. Hydraulic systems manage the machine’s ascent, descent, and drum rotation, with controls located in the right basket for the operator.

For enhanced efficiency, the device comes with an electric stimulator fitted with two electrodes. This is designed to contract the muscles during the dehiding process, reducing the likelihood of backbone damage.

To complete the setup, it’s essential to pair the dehider with a load reliever, which alleviates the strain on the network and trolleys from the pulling force.

Technical Specs

The device is constructed with a fixed frame and a mobile frame, available in either galvanised steel or stainless steel, and is powered by a telescopic cylinder. Within this framework:

- A stainless steel drum, energised by one or two hydraulic motors, is integrated.

- Baskets made of stainless steel feature a detachable stainless steel floor and a wastewater collection tank to facilitate thorough cleaning.

- Every basket is equipped with comprehensive hygiene tools.

- The baskets and drum move in unison.

- There’s a tetanisation arm fitted with two specially designed, non-abrasive electrodes to prevent spinal column damage.

- The load reliever is designed to elevate cattle ankles, alleviating pressure on the handling hooks and rail. A mechanism ensures the ankle remains securely locked.

Moreover, this device is versatile and can be tailored to fit a variety of conveyor systems.

Delivery & lead times

We do our best to deliver within the lead times listed above. Although if you have any specific requests, please get in touch and we can see what we can do.

For international shipping, lead times may vary.

international shipping